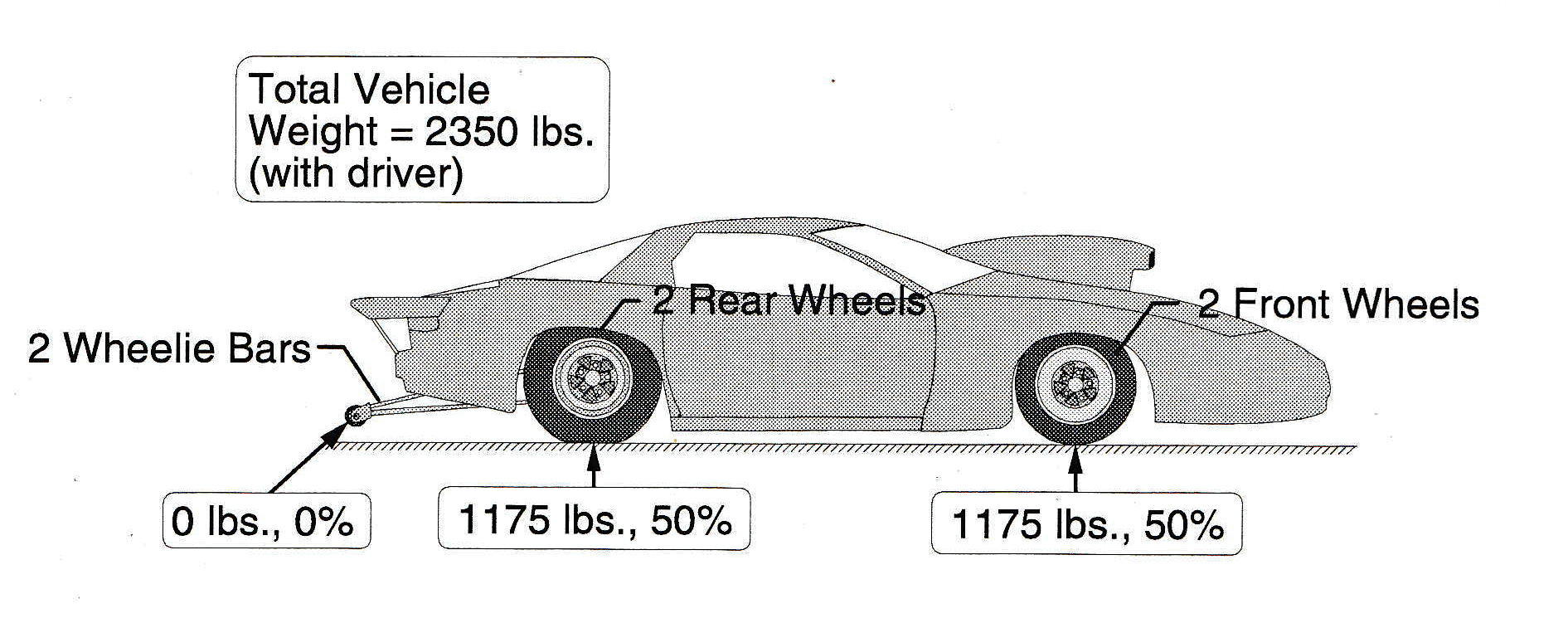

Measured from the front axle, with front as negative and rear as positive, it pick the spot somewhere almost at the mean of the front and the rear wheels. In order to calculate the weight distribution for the axle, horizontal center of gravity needs to be determined. Center of gravity can be read in two ways – horizontal and lateral. It does not necessarily need to be a material component of that truck.

However, that’s something which goes with the axle capacity and weight reference points of a certain truck type.Įach truck has a center of gravity which is an average location of the weight it holds. Much of what you do to plan loading on your truck depends on the center of gravity. 5,500 kgs of front axle capacity and an 8,000 kgs of rear axle capacity while a tandem-drive truck goes with a 7,700 kgs on each axle making it a total of 13,500 kgs. A single-drive truck generally has an approx. This can be simply done by putting a wood log/plank weighing more towards the midpoint, moving vertically.Īxle capacity can be measured by looking at the tension limit offered by both the axles individually and the legal weight limits – and pick the one which is lower. For a jinker, it is important to put logs in a pyramidal style to manage the weight vertically – complying with center of gravity. For something like a stack of boxes filled with heavy material like metallic coils, it should be planned in a way so that nothing derails the shared grip.

As per the conventions, for anything that needs to be kept lying flat (think of big iron rods) should be bedded with a suppressing weight over the front end of it. Weight distribution in trucks could be balanced-off looking at the type of good that is being loaded. Starting reference points for weight distribution in trucks however could be picked as: A weight distribution analysis ascertains if the loadings are being done properly as per the vehicle built and load balance dynamics. Weight of the vehicle needs to be distributed fairly between axles to comply with manufacturer’s axle ratings and the weight laws. Technically it’s the total weight imposed on the ground at an axle, group of axles or an individual wheel. What exactly weight distribution in trucks means Talking of that, weight distribution analysis becomes crucial for your truck’s good health and even drive. A routine level disguised practice, commonly held by most of the drivers across India without properly considering the ideal weight distribution techniques. Talk of any place – Delhi, Jaipur, Mumbai or Pune – all just put same with trucks being treated alike, loaded with unmanaged weight, causing problems for users and the equipment installer followed by abnormal wear and tear and shortened life of the vehicle. There is some kind of weight they carry to and fro on a regular basis.

0 kommentar(er)

0 kommentar(er)